About Us

- Established in 1989 Mumbai-India today Adarsh Industries is a Leading Manufacturer & Exporter of pressure gauges, temperature gauges and gauge accessories.

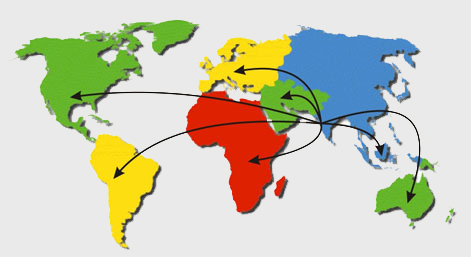

- Exports to more than 65 countries including North/South America, Europe, Africa and Asia.

- Company is headed by Mr. Mahendra Shah having more than 31 years of Industrial Experience along with Mr. Chintan Shah a Technocrat who has now made ADARSH a worldwide name.

- Modern techniques and machinery are used for production of gauges while continuous Research & Development has helped to manufacture new enhanced models of pressure gauges.

- Indian IS-3624, DIN 837 and ASME Standards followed in general for production of gauges

- Indian Navy Defence Approved.

- Pressure Gauges have passed third party tests- Shock test, vibration test, dust & water jet test, endurance test.

- Strict Quality Control is ensured for manufacturing gauges.

- Adarsh Industries also deals in Replacement Spares for Refrigeration Compressors since last 25 years.

Application Market Areas

ADARSH Gauges have found its application in numerous industries. We have developed gauges for all industrial applications including severe applications where there is heavy corrosion, high accuracy is required etc.

- Sanitary Industries –food, pharma, breweries, dairy industries…

- Process Industries –chemical, fertilizer, sugar, paper & pulp, power, petro, cement, thermal industries

- Refrigeration Industry –iceplant, cold storages, chlling plants, fisheries…

- Marine Industry – Ships, Engines

- OEM Equipment & Machinery Manufacturers – Hydraulic & Pneumatic Instruments, Machninery

Visit our Product Page for more details of our products.

Quality * Accuracy * Reliability

At ADARSH Quality Comes First

At Adarsh Industries IS:3624, DIN 837, ASME Standards are followed in general for production of gauge. Situated in Mumbai the commercial capital of India, with our highly skilled technical experts we have put an effort to meet the quality of pressure gauges as per international standards. Each gauge is calibrated against high precision test gauges followed through leak test, overload test and accuracy test. Bourdon tube systems are heat-treated & stress relieved for greater durability.

Digital Test Gauges wth accuracies upto 0.05% are used for Calibration of gauges. Master Gauges are tested on Dead Weight Testers. Our Test gauges & Dead Weight Testers are periodically calibrated by NABL Accredited Labs.

Why select ADARSH Gauges ?

Our Pressure Gauges are certified by SQAE Mumbai & IDEMI Mumbai for the following tests. ‘ADARSH’ pressure gauges passed the following tests successfully in just one attempt.

All ADARSH Gauges are Tested individually & certified for their Accuracy & Guaranteed for one year against manufacturing defects if any. This guarantee however will not apply if the gauges are misused or mishandled or damaged due to excessive corrosion, excessive vibration, excessive temperature, pressure beyond full scale.

Shock Test (Free Fall Method)

Drop height 600mm, Gauge Mounting at – a) 6 O’ Clock b) 3 O’ Clock c) 0 O’ Clock & with dial facing upward, Nos. of Drop- One each in the above position

Results: No Visual Mechanical Damage Observed

Vibration Endurance Test by Sweep

Frequency: 5-60-5 hz, Amplitude: 1.5g constant acceleration, Sweep rate: 10ct/min, Duration: 2hrs in each axis

Results: No Visual Mechanical Damage Observed

Dust Proof Test

The sample gauge was ket in dust chamber, talcum powder was maintained in supsension by air cuurent. The sample was connected to a vacuum of 200mm of water column for two hours.

Results: At the end of the test the gauge was checked for dust penetration, the gauge complied this test successfully.

Protection Against Water Jet

The gauge was washed by water at 1kg/cm2 by a nozzle from all direction at a distance of 3 meters.

Results: At the end of the test the gauge was checked for water penetration, the gauge complied this test successfully.

Endurance Calibration Test

Pressure Fluctuation of about 50% of the pressure range was generated and the same was applied alternately between 25% and 75% of the instrument scale at a frequency about 60 cyles per minute. The Endurance Test was run for about 300 hours on non-continuous basis till completion of 10,80,000 cylces of operation.

Results: After completion of test the accuracy of the gauge was checked and change in maximum accuracy after this test was found to be 0.028% of span.

Exports

ADARSH Products are exported to more than 65 countries worldwide

Belgium

Cambodia

Finland

France

Greece

Italy

Ireland

Libya

Malaysia

Maldives

Mexico

Morocco

Niger

Netherlands

Oman

Peru

Puerto Rico

Russia

Serbia

Singapore

Spain

South Africa

Saudi Arabia

Tanzania

Trinidad & Tobago

U.A.E

UK

USA

Uganda

Vietnam

Zimbabwe

Research & Development

Research and Development

Since the company is led by technocrats R&D forms a key part of our company. Thanks to our continuous R&D efforts today we have been a pioneer in manufacturing advanced gauges. Our R&D team consists both experienced and young people. At Adarsh we like challenges and our R&D team is well equipped to fulfill any requirement.

Key developments

- Socket Welded to Case

- External Zero Adjustment

- Capsule Pressure Gauge with inbuilt over pressure protection upto 5 times Over Pressure of Full Scale.

- Diaphragm Seal with Miniature Diaphragm

- High Pressure Comparison Tester without priming pump

- Maximum pointer for 2-1/2″, 4″, 6″ gauges with possibility of glycerin filling

- Indeginuous developed Quadraple Contacts 2NO+2NC for electrical contact gauges.

- Designed temperature gauges for high vibration applications for Diesel Engines on Ship

- Development of Duplex Gauge with Double C Shaped Bourdon for use on Multistage Refrigeration Compressors